Generator Low Voltage: 9 Common Causes and DIY Fixes

Generator low voltage is known as a silent killer for voltage-sensitive appliances like UPS, Chargers, refrigerators, Microwaves, etc. In worst cases, the low voltage could burn the ICS or inner organs of the appliances within no time.

In this guide, we are going to share with you the most common causes of low voltage on a generator and DIY methods to fix them without hiring a professional.

Causes and Solutions of Generator low voltage

1. Overloaded/Overburden on the Generator:

If you are pulling more than recommended load from the generator, you may have to face cranking sounds or even voltage drops as well.

As you might know, voltage drop could be a silent killer for expensive appliances that’s why modern generators have overload protection to make sure the generator should turn off once the load exceeds the limits.

How to Fix It:

Thankfully this isn’t a technical fault you can fix it easily by managing the load, keep a bird’s eye on the load it shouldn’t exceed the limits. Also if you have a modern machine the overload protection could do the work itself.

NOTE: If the machine is overloaded, unplug the appliances and reset the generator.

2. Faulty Circuit Breaker:

Almost all of the generators have a series of Circuit breakers to protect against any damage like overload, high voltages, etc.

If a generator produces lower, fluctuated, or no voltages, your first step is to examine the circuit breaker, if you found tripped or burned breaker, you need to turn off the generator asap.

How to Fix It:

- Double-check the location of the breaker, if it is in the “OFF” position make sure to set it to the “ON” position.

- Take a multimeter and measure the resistance of the lead wire connections located inside the electrical panel, also take readings from the electrical panel as well. If you found any resistance the breaker is in good condition, however, if the reading is ‘OL’ (overload) or Infinity, the breaker needs to be replaced.

3. Loose Connections:

Corroded or Loose connections are also the leading causes of imbalanced resistance in the circuit.

How to Fix It:

Check out the wirings and connections of the both generator and your house, if you found extremely rusted wire or circuit breakers make sure to replace them.

4. Faulty AVR:

The purpose of AVR is to regulate the output voltages so that appliances could eat uncontaminated safe power.

All of the AVRs have a screw to adjust/tune the voltage output as per the requirements; however, if the AVR is not working properly the generator may produce imbalanced or low voltages.

How to Fix It:

- Before testing the AVR make sure to test the main/primary circuit breaker of the generator first. If it’s fine make sure to also test the wiring within the electrical panel and from the primary breaker to the stator.

- Remove the AVR and inspect it, if it’s not tuned as per the requirement, make sure to tune it. If the problem still exists check the condition of the rotor brushes, if they seem a bit worn make sure to replace them as well.

- If you have done the above tests and still the problem is there, the final test is to take the reading of the stator itself, if the stator is producing power that means the real culprit is AVR and it needs replacement.

5. Faulty Capacitor:

Like AVR capacitor is also responsible for controlling the output voltages of the generator, if the capacitor is malfunctioning you may have to face unstable or sometimes zero voltages if it’s busted.

How to Fix It:

The location of the capacitor is the same as AVR; you just need to remove the +VE and –VE wirings of the capacitor running from the rotor.

The next step is to fire up the generator and take the reading of the +VE and –VE wirings by using a millimeter. If the reading is between 4 to 5 volts, the capacitor is the culprit and it needs to be replaced.

6. Ground Fault:

Due to the three-phase grounding both current and voltage may drop.

How to Fix It:

Make sure to inspect whether the grounding discharge is grounded or not. If you found anything disconnected make sure to ground it properly. You can follow our detailed guide to safely ground the generator in an instant.

7. Mechanical Malfunction:

The following could be the potential mechanical faults the generator couldn’t produce the desired voltages.

- The generator with Bad “Generator Turbo” can’t produce the required air pressure to operate the machine at the maximum capacity.

- The oil, air filter, carburetor, and fuel lines are clogged. As a result, the fuel and air mixture will be imbalanced, which leads to improper combustion.

How to Fix It:

Your first step is to replace the oil filter and clean the air filter, carburetor, and fuel lines. If the problem is still there, you should seek help from a professional.

Recommended Read: Cleaning the carburetor of the generator

8. Alternator Malfunction:

The alternator is the crucial organ of the generator to charge the capacitor if it isn’t working properly the generator may output lower or no voltage. In most cases, the rotor’s residual magnetic field fades away due to the following reasons.

- The generator stays for a long time

- The generator is being operated for a longer time with no load.

- The appliances plugged in even the generator is in off condition.

How to Fix It:

Restore the residual magnetism by flashing it with an external DC supply i.e. 12V battery or drill. We have written a detailed guide about flashing the generator with an external DC supply; make sure to have a look.

9. Problems with the Stator:

There are mainly two types of Stators one is brushed and the other is brushless. The stator consists of three windings and a sufficient area inside it to rotate the magnetically charged rotor.

If something is wrong with the stator’s windings your generator may produce lower or no voltages in most of the cases.

How to Fix It:

Inspection of the stator is not an easy task; however, you can do a few basic tests at home like inspection of the winding condition and resistance test of the coil with the help of a multimeter.

If you found infinity or high resistance, the stator is bad, however, if you found zero or close to zero resistance the stator is in good condition.

NOTE: If you suspect the stator is the culprit and you don’t know how to repair or test it, we recommend seeking help from the expert.

Recommended Read: Generator Output Voltage Too High

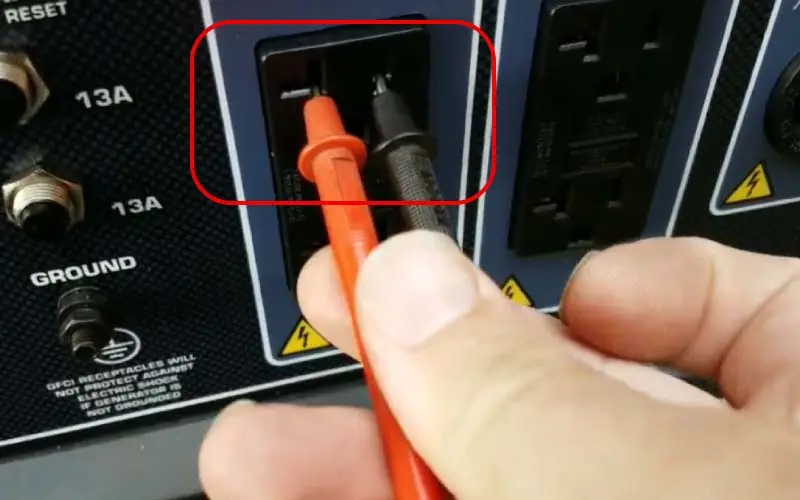

How Do You Test for Low Voltage in Generator?

Take a multimeter and start the generator, insert the red probe into the left hole of the generator’s outlet and the black probe into the right. If the outlet is 120V it should provide 119 – 120V.

Effects of Generator’s Low Voltage on Appliances

- The voltage-sensitive appliances may malfunction or meltdown in the worst cases.

- Heavy motorized appliances like water pumps, refrigerators, air conditioners, etc. may not provide the desired output.

Verdict

Generator low voltages couldn’t not only hurt the efficiency of the appliances but also could harm them dangerously.

Moreover, the generator under voltage can happen suddenly without a warning, We highly recommend getting a generator with modern features like an app to monitor the voltage, oil condition, load, etc., or at least get one with a built-in voltmeter so that you will have a bird’s eye on the voltages.

Frequently Asked Questions – [FAQs]

Is It Costly To Repair A Generator With Low Voltage?

It depends, if the problem is because of the high load you can simply fix it without spending a penny.

On the other hand, if the culprit is an inexpensive part like a breaker, AVR or Capacitor you will have to spend a few bucks, however, if the problem is with the alternator or stator, you may have to spend a few hundred bucks.

Can a Bad Ground Cause Low Voltage?

Yes, improper grounding is the leading cause of generator low voltage output.

Kashif has been a valuable asset to the electric generator industry for over 5 years. Now, As a skilled energy engineer, he’s been on the front lines of diagnosing problems, fixing broken parts, and performing routine maintenance tasks to keep generators running smoothly.