Why is My Generator Not Producing Power? – [Main Reasons]

If you want to know the answer to the question “Why is My Generator Not Producing Power” read this article to the end to find the 8 reasons. We have created a very helpful guide using to the data to help you understand you problem.

Are you experiencing complete power outages at your home or business due to your backup generator not producing power? Don’t Panic.

Many generators can experience technical issues that prevent them from producing power.

In this article, I am going to explore the 8 most common reasons why generators fail to produce power and provide tips on how to troubleshoot and fix the problem.

From faulty fuel lines, tripped breakers, defective AVR, and loss of magnetism to low oil levels, we’ll cover it all, so you can get your power back up and running in no time.

Below is a short list to Tackle the problem.

8 Reasons Why Generators Don’t Produce Power?

- Tripped Breakers

- Faulty Outlets

- Loss of Residual Magnetism

- Problems in Connections

- Defective AVR

- Defective Capacitor

- Worn out Brushes

- Faulty Breakers

1. Tripped Breakers

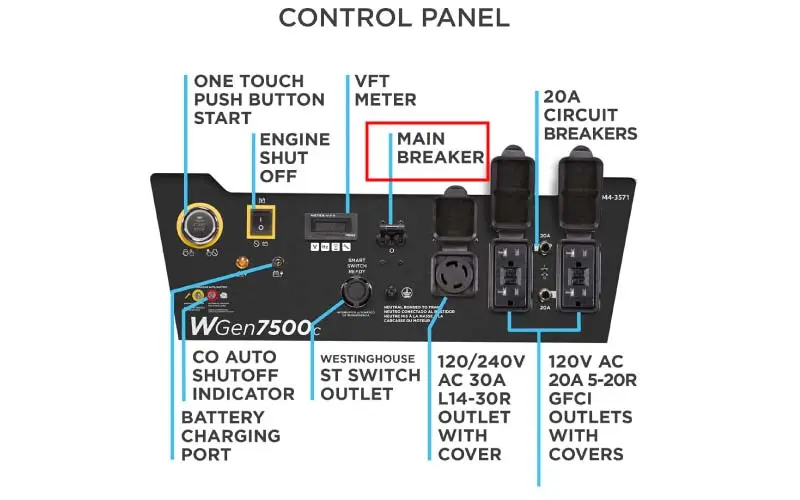

If your main circuit breaker on the control panel of the generator is at the OFF position, you got yourself a tripped breaker.

It is like a safety mechanism. When you overload your generator, the safety breaker will trip to avoid any damage.

To avoid such conditions, you have to be careful when drawing power from your generator. If your unit is rated at 2000 watts, don’t push it beyond 1800 watts. Leave some for safety purposes.

Many manufacturers are now adding GFCI (ground fault circuit interrupter) breakers instead of common circuit breakers (Fuses).

The reason is to avoid electrocution because these breakers sense the amount of current flow. So if there is any overflow of current, the breakers will trip.

Why GFCI Breakers Trip?

- Fried or broker power cords causes power leakages.

- Sometimes the GFCI outlets are at fault. Replace them and try again.

- Like any common breaker, GFCI breakers are also sensitive to overloading.

Special Note: If you are a technical person, you can bypass the circuit breaker in emergencies, but stay away from it if you don’t anything about power and circuits.

2. Faulty Outlets

Faulty, worn-out, or damaged outlets are one of the biggest reasons why a generator doesn’t produce any power even if it is working.

Faulty outlets can also cause a generator to not produce power if they are not correctly connected to the generator or if they are damaged. It is important to ensure that all outlets are correctly connected and in good working condition before attempting to use a generator

If you want to check outlets, take some readings using a multimeter. If you get some readings, then outlets are fine.

3. Loss of Residual Magnetism

A generator is a device that converts mechanical energy into electrical energy. It does so by using the principle of electromagnetic induction, where a rotating magnetic field induces a current in a conductive coil.

The rotating magnetic field is created by a set of magnets, called the rotor, which rotates inside a stationary set of coils, called the stator.

One of the key factors that affect a generator’s ability to produce power is the level of residual magnetism in the rotor.

Residual magnetism refers to the magnetic field that remains in the rotor after the generator has been shut down.

When the generator is running, the residual magnetism interacts with the magnetic field created by the stator, which can affect the generator’s performance.

If the residual magnetism is too high, it can cause the generator to produce more power than it is designed to handle, which can lead to damage to the rotor and stator.

Additionally, high residual magnetism can cause the generator to produce harmonic distortions, which can harm other electrical equipment connected to the generator.

On the other hand, if the residual magnetism is too low, the generator may not produce enough power to meet the load demand.

Low residual magnetism can also cause the generator to produce less power than it is capable of, which can lead to wasted fuel and increased operating costs.

Recommended Read: Generator Low Voltage?

Reasons for Losing Residual Magnetic Field in a Generator?

- If you haven’t used the generator in a long time, the residual field may fade away. It is one of the common reasons.

- Running a generator without a load for a long time.

- When you plug in some appliances even if the generator is OFF, the residual magnetism tries to transfer to those appliances.

If you are facing such issues, you can restore the residual magnetism in your generator using two simple DIY methods in your home. These methods are usually called flashing a generator.

Re-Magnetizing a Generator with a Drill

- Wear safety gloves, and remove the drill bite from the drill.

- Start the generator, and let it run for a minute.

- Plug the drill into the generator outlet and hold down the trigger.

- Twist the drill’s chuck in a forward direction using your hands.

- If the drill gets some power, you have successfully restored the magnetism.

- Repeat the process 3 to 4 times if it doesn’t work.

Re-Magnetizing a Generator with a 12-volt Battery.

- Remove the Generator’s alternator cover.

- Disconnect the wires that connect AVR and brushes together.

- The black wire is mostly negative but check the user manual. Take a picture too so that you can identify them for later.

- Plug a 100W light into the generator outlet.

- Take a 12-Volt car or any other battery. Attach the +VE (red) terminal of the battery with the +VE end of the rotor where the red cable was first attached.

- Turn ON the breaker and start the generator.

- Now attach –the VE (black) terminal of the battery with the black end of the rotor where the black cable was first attached.

- It should just be a tap of the wires, the re-magnetizing of the generator should be successful at this point.

NOTE: Wear protective gloves or be very careful.

Read this research about residual magnetism if you want to increase your knowledge.

4. Problems in Connections

Sometimes the connection themselves are at fault. Damaged, burned, or worn-out cord could be a reason for that, or sometimes you will find dirt, debrief, and bugs in the outlets.

Make sure to check the connections and the outlets before making a decision.

5. Defective AVR

AVR (automatic voltage regulator) is used to regulate the voltage to a steady level so that sensitive appliances don’t experience voltage fluctuations.

If the AVR is busted or malfunctions, the generator will not produce any output voltage.

How to Check If the AVR is OK?

- You will have to remove the generator’s alternator cover to access AVR.

- Unhook the AVR by removing positive and negative cables from the carbon brushes.

- Start the generator and take a multimeter.

- Place the red (+VE) and black (-VE) probes of the multimeter on the right and left sides of the carbon brushes to check the voltage.

- If the reading is between 5 to 10, there could be something wrong with the rotor or brushes.

- To check the winding (L1, L2, R1, R2) place the red probe of the multimeter on the L1 and the black probe on the L2.

- After that, place the red probe on the R1, and the black on the R2.

- The winding is fine if the reading is between 3 to 5 volts.

6. Defective Capacitor

Some generator comes with a capacitor instead of an AVR. The capacitor is located at the position as AVR (behind the alternator cover)

Take a multimeter and connect the positive and negative (Red and Black) probes to the ends of the brushes. Fire the generator and check the readings.

If the reading is less than 5 volts, your capacitor is at fault.

WARNING: Don’t touch the capacitor with bare hands or you will get an electric shock.

7. Worn out Brushes

Carbon brushes are made of carbon and they are used to conduct electrical current between the stationary and rotating parts of the rotor.

The positive and negative wires of the AVR are connected with the assembly of the carbon brushes. You can easily find them by removing the alternator cover.

If the carbon brushes show the following signs, you will need to replace them:

- Small in size

- Broken

- Cracks

- Lose brushes

- Melted or burned

8. Faulty Breakers

Faulty breakers are another reason why generators don’t produce any power. If the breaker is not functioning properly, it may trip and shut off the power supply to the generator, causing it to stop running.

This can happen due to a variety of reasons such as a short circuit or an overload. In order to fix the issue, the faulty breaker will need to be identified and replaced.

Check if the main breaker is tripped, if that is the case, you will need to replace it. Check our article If your generator won’t start at all.

Verdicts

There could be multiple reasons why your generator is not producing power, from a clogged air filter to a malfunctioning alternator.

By systematically checking each potential issue, you’ll be able to pinpoint the problem and get your generator up and running in no time. Remember to always consult the owner’s manual or seek professional help if needed.

Frequently Asked Questions (FAQs)

When should you flash a generator?

If the generator is not producing power even if the AVR, carbon brushes, outlets, and breakers are working, you should flash the generator using a drill or a 12V battery to re-energize the magnets.

What is a brushless generator and how does it work?

A brushless generator, also known as a synchronous generator, uses permanent magnets to generate electricity.

The rotation of the rotor within the stator generates a magnetic field, which induces an electrical current in the stator windings.

Why is my brushless generator not producing power?

There are several reasons why a brushless generator may not be producing power, including lack of proper maintenance, a faulty exciter, a damaged rotor or stator, tripped or defective breaker, a defective AVR, loss of residual magnetism, or a malfunctioning control system.

How can I troubleshoot my brushless generator?

To troubleshoot your brushless generator, you should check the exciter and rotor for damage, ensure that all internal components are properly lubricated and cooled, and check the control system for any faults or malfunctions.

How often should I perform maintenance on my brushless generator?

The frequency of maintenance required for your brushless generator will depend on the manufacturer’s recommendations and how often it is used.

Typically, it is recommended to perform regular maintenance such as oil changes, inspections, and cleaning of the generator every 100 hours of use or at least once a year.

Why is My Generator Running But Not Producing Power?

It could be an issue with the fuel supply, such as a clogged fuel filter or a malfunctioning fuel pump.

The generator’s alternator could be malfunctioning, preventing it from producing electricity. It could also be an issue with the generator’s control panel or voltage regulator.

Additionally, the generator may not be connected properly to the load or the generator’s circuit breaker may have tripped.

Fareed, the highly skilled electrical expert, boasts 5 years of extensive experience in proficiently maintaining, repairing, diagnosing, and installing a diverse range of electrical systems.