How to Test a Generator? – [5 DIY Methods For Beginners]

Discover how to test a generator like a pro with our comprehensive guide. Learn essential tips, tricks, and best practices to ensure optimal performance during power outages.

A generator’s ability to produce consistent and reliable power is essential for a variety of applications, from powering critical medical equipment to keeping the lights on in your home during a storm.

As a generator expert, I know that testing a generator involves a series of technical procedures to evaluate its performance, safety, and reliability.

To test a generator, several technical procedures need to be performed, including load testing, insulation resistance testing, runtime test, and frequency and voltage testing.

In this guide, we’ll cover these tests in detail, as well as common problems that can arise with generators and how to troubleshoot them.

Whether you’re a technician or a DIY enthusiast, this guide will provide you with the technical knowledge you need to effectively test a generator.

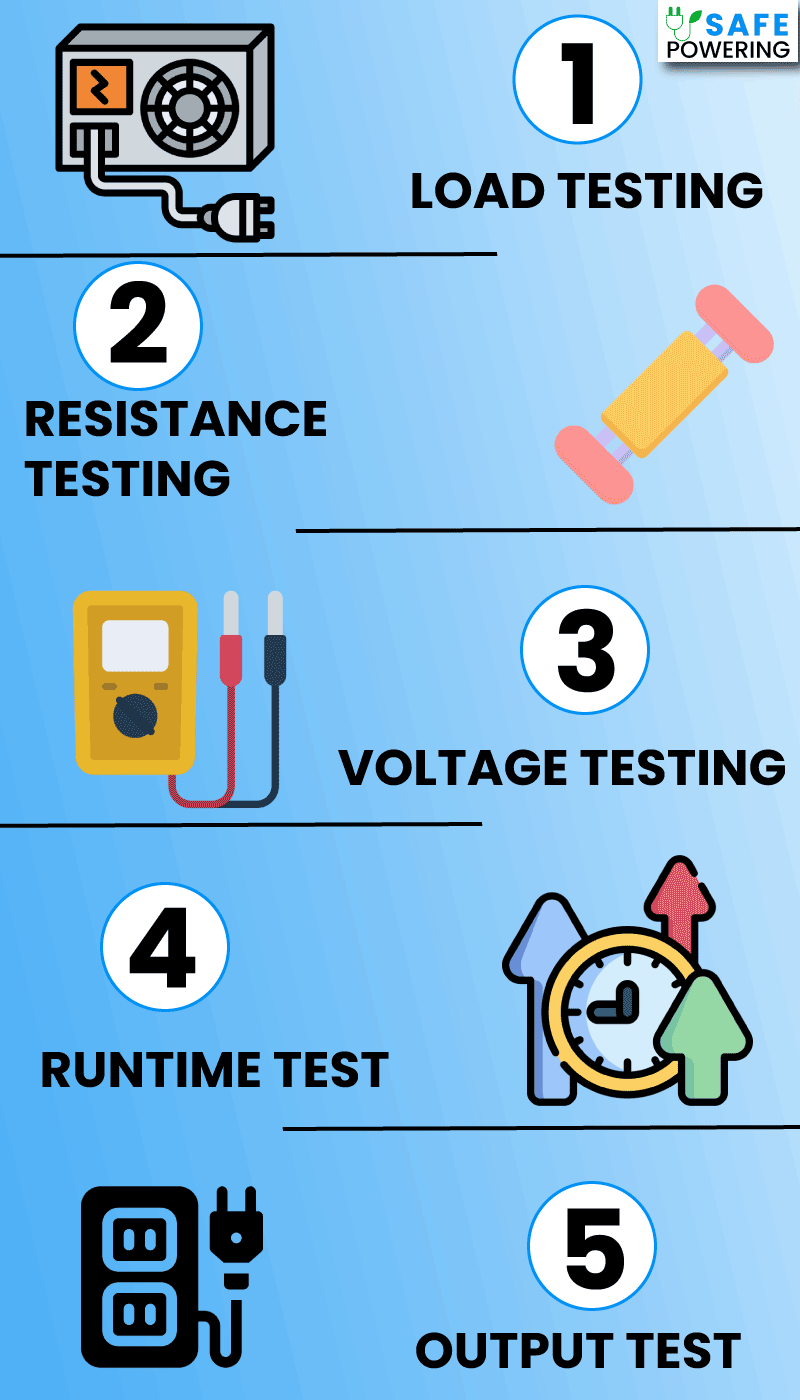

How to Test A Generator? – [5 DIY Steps]

1. Load Testing:

The load is extremely simple. You will just have to draw out power until either the overload alarm turns ON, or the generator shuts OFF. Here is how I did it with my Duromax XP1300EH.

- My Duromax XP1300EH is rated at 13000 starting, 10500 rated watts, 87.5amps at 120V, and 43.75amps at 240V on gasoline.

- On propane: 12350 starting, 9975 rated watts, 83.13 amp at 120V, 41.45 at 240V.

- I connected a standard fridge, a microwave oven, a 10000BTU AC, a coffee maker, a small dryer, a printer, and some lights.

- On gasoline, I managed to get 10490 running watts before the overload alarm turned ON.

- On propane, I was able to get 9580 watts before the overload alarm.

So the point is, for a load test, your generator should come close to giving out the actual amount of power it is rated. If it is unable to provide a minimum of 80% of the power it is rated ON, then there is something wrong with your machine.

Before conducting the load test, it’s essential to ensure that the generator is properly connected to the load bank and that all safety precautions are in place. You need to make sure your generator is not overloaded as well. It creates all sorts of other problems.

You should also monitor the generator’s voltage and frequency during the test. If the voltage or frequency deviates from the recommended levels, you may need to adjust the generator’s settings.

Before doing any kind of test, you should know about general generator safety.

2. Insulation Resistance Testing:

Insulation resistance testing is another critical component of generator testing. It involves measuring the electrical resistance of the generator’s insulation system to evaluate its integrity.

Insulation resistance testing is crucial because any weakness or degradation in the insulation can lead to electrical faults and even electrocution.

To conduct insulation resistance testing, you will need a megohmmeter, which is a device that measures electrical resistance. The megohmmeter should be capable of measuring insulation resistance up to several megohms.

During the test, you will need to disconnect the generator from its power source and discharge any stored electrical energy.

Then, you will connect the megohmmeter to the generator’s insulation system and measure its resistance.

3. Frequency and Voltage Testing:

Frequency and voltage testing are also essential components of generator testing.

These tests evaluate the generator’s output frequency and voltage to ensure that they are within acceptable limits.

Deviations in frequency and voltage can cause damage to electrical equipment and even result in electrical fires.

To conduct frequency and voltage testing, you will need a voltmeter and a frequency meter.

These meters should be capable of measuring the generator’s voltage and frequency levels accurately. During the test, you will connect the meters to the generator’s output terminals and measure their voltage and frequency.

4. Runtime Test:

The runtime test is the total number of hours your generator is able to run to a full tank of gas or diesel.

- Fill up the tank and run your generator at 25% load.

- Now run it at 50% load, and then finally, at 90% load.

- Notice the number of hours recorded for each turn.

- If the hours match that of the user manual or online reviews, then the test is successful.

- If not, there might be something wrong with the generator.

My Duromax XP1300EH ran for 8.4 hours at 50% on gasoline, and 6.7 hours on propane at 50% load. I was satisfied with the result as it matched the user manual and online reviews.

5. Output Test:

To conduct an output test, you will need to connect the generator to a load bank that is capable of simulating the electrical load that the generator will encounter during operation.

You will also need a voltmeter and a frequency meter to measure the generator’s voltage and frequency output.

During the test, you will need to adjust the generator’s settings to ensure that it is producing the correct voltage and frequency output.

You should also monitor the generator’s performance under load to ensure that it is operating reliably.

If the generator passes the output test, it produces the correct voltage and frequency output and is suitable for powering electrical equipment.

However, if any issues arise, you may need to adjust the generator’s settings or troubleshoot any problems.

How to Troubleshoot AVR (Automatic Voltage Regulator)?

I found this research about AVR design and performance. Read it if you want to increase your knowledge.

Conclusion

Testing a generator is crucial for ensuring its proper functioning and reliability.

Load testing, insulation resistance testing, and frequency and voltage testing are all critical components of generator testing.

By following the procedures outlined in this article, you can effectively test your generator and ensure that it is safe and reliable for use.

It’s essential to perform regular generator testing to prevent equipment damage, electrocution, and other hazards.

Frequently Asked Questions (FAQs)

Why Do I Need To Test My Generator?

Testing your generator ensures that it is working properly and producing the correct amount of power. This is important for the safe and efficient operation of the generator and for the devices or appliances that are being powered by it.

How Can I Test My Generator?

There are several ways to test a generator, including:

Load testing: This involves connecting a load to the generator and measuring its performance under varying loads.

Output testing: This involves measuring the voltage and frequency of the generator’s output to ensure that it is within the correct range.

Engine testing: This involves checking the engine’s oil level and performing a visual inspection for any signs of damage or wear.

What Tools Do I Need to Test My Generator?

The tools you need to test your generator depend on the type of testing you are doing. Load testing requires a load bank or a variety of loads to simulate different power demands. Output testing requires a multimeter or voltmeter to measure voltage and frequency. Engine testing requires basic hand tools and knowledge of engine maintenance and repair.

Can I test My Generator Myself or Should I Hire a Professional?

It is possible to test your generator yourself if you have the necessary tools and knowledge. However, if you are unsure about how to test your generator or are not comfortable working with electricity or engines, it is best to hire a professional to perform the testing for you.

How Often Should I Test My Generator?

It is recommended that you test your generator at least once a year, preferably before the start of the storm season or any other time when you may need to rely on it for backup power. Additionally, you should test your generator after any significant repairs or maintenance.

Fareed, the highly skilled electrical expert, boasts 5 years of extensive experience in proficiently maintaining, repairing, diagnosing, and installing a diverse range of electrical systems.